With the competition's harrows, changes to the tine angle or section angle will inadvertently affect the set down pressure, and visa versa.

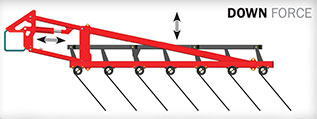

With the Bourgault XR Series Harrows, the ADF™ feature isolates the application of down or up force from tine angle or section angle, so adjustments to one setting does not affect the other two. You can set the XR Series Harrows more quickly to achieve desired results, particularly in challenging and variable conditions.

Once the hydraulic pressure is set, downforce remains constant even through hilly land and water runs.

Settings Guideline

The beauty of the XR™ harrow series is that changes to one setting do not affect the others.

Once the optimal tine angle is found, changes to the Adjustable DownForce (ADF™) and boom angle (pitch) will have little impact on the tine angle, shortening the time and reducing the frustration to achieve a desired field finish.

Below is suggested guidelines for setting the XR harrow:

Set the tine angle based on the volume of straw that you want held in the harrow to achieve the desired results. To increase the amount of straw being carried, adjust the tines so that they stand taller, decrease the tine angle to reduce the amount of straw being carried. These changes do not change the down pressure applied by the XR™ Harrow.

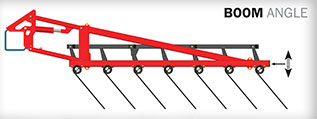

Set the boom angle to dictate where the straw is being carried. Roll it forward to carry the straw in the front of the section; this is useful for tougher field and straw conditions. Roll the boom back to carry the straw at the rear of the harrow frame; this is more useful for breaking up straw in drier field and straw conditions. Again, these changes do not change the down pressure applied by the XR™ Harrow.

Adjustable DownForce™ pressure (down/up) is adjusted with the ADF™ valve, either in the cab on the 500 Control Box or on the hitch. Increase the pressure to do more incorporation, soil scratching and collecting of straw. Decrease the pressure to reduce damage to standing stubble.