No other seeder controller system on the market provides the features offered by the X35 Apollo seeder controller. These include:

Dual Auto Section Control (Dual ASC™)

Reduce your input costs by minimizing double application where drill overlap occurs.

- Set the on/off timings to your needs.

- Control seed opener and Mid Row Bander® Fertilizer Applicator timings separately so that you can ensure that there are no seed misses and you won't have to overapply fertilizer in the headlands.

- A quick reference guide is provided with suggested starting values and calibration procedure.

Product Blockage Monitoring

Bourgault offers several different options to monitor product delivery on the air kit.

- The Topcon blockage monitors (shown) provide an optical sensor installed on one tertiary line of each manifold.

- The Agtron™ Legend option comprises of seed flow sensors on each tertiary line, giving you application monitoring to every seed boot.

Both systems work in conjunction with the Bourgault sectional control option, so nuisance alarms are not generated when sections turn off and on.

Tank Optimizer

The Tank Optimizer calculates product fill recommendations based on product type and target rates entered so you can quickly determine which option will minimize your stops in the field. The Tank Optimizer provides several tank groupings and the projected coverage for each compartment for your consideration.

Note: The 9000 I Series does not have any interconnected tanks, but the Tank Optimizer can still be of benefit by suggesting the appropriately sized tank for products or how they could be split depending on set rates.

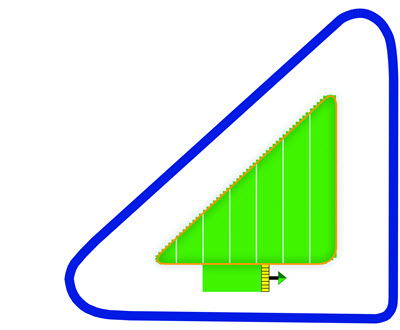

Headland Manager

Eliminate uneven emergence by seeding the headlands last. Working with an established field border, the Producer enters in the number of headlands desired, then proceeds to seed the inner section of the field. The X35 automatically shuts off metering as the drill enters the headland. When the inner area is complete, the Producer can then set the X35 to allow seeding in that area.

There are three distinct advantages of seeding the headlands last with Headland Manager:

- Reduced compaction in the headlands from trucks and seeding systems, delivering the best emergence possible on the headlands;

- Elimination of the openers being dragged through the seeded area of the field;

- Conformation of the field boundary, when the property line is unclear or night time seeding.

Calibration Wizard

Calibration Wizard provides a logical step-by-step guide for completing a multi-tank calibration. A “charging” feature ensures that the metering augers are primed with product so an accurate sample is collected.

Operate the Calibration Wizard beside the tank with the Xtend™ Feature. When the X35 is linked to a tablet or smartphone, you can complete the entire calibration without running to the tractor cab.

Quick Start Wizard

Quick Start is designed to prompt the Operator to step through each desired operation prior to putting seed in the ground. Develop an efficient process and use it consistently throughout the whole season, each season.

Refer to the Customer Service video for more information on Quick Start.