- Fertilizer is delivered with a separate distribution system to the Mid Row Bander® Fertilizer Applicators mounted on the front row of the drill.

- The MRBs® (red arrows) are positioned between every two seed openers (green arrows).

- Enough fertilizer for the two rows are delivered by each MRB® Fertilizer Applicator.

- Safe amounts of starter fertilizer can be metered with the seed for immediate access.

If rates of starter fertilizer beyond what can safely be placed with the seed are required, rates can be split to include some starter fertilizer being placed in the mid row band.

This approach takes best advantage of the

nitrification process, necessary for making the nutrients accessible to the plants.

The Nitrification Process

All urea based fertilizers (46-0-0 and 28-0-0) begin conversion to plant available forms in the presence of the urease enzyme, which first converts urea to NH3. Bacteria then drive the process of nitrification, which ultimately leads to nitrate; nitrate facilitates plant growth. Mid row placement of the crop’s main nitrogen requirements is the optimum location for eliminating the risks involved with too close seed/fertilizer proximity and facilitating timely access to nitrate for the developing plant.

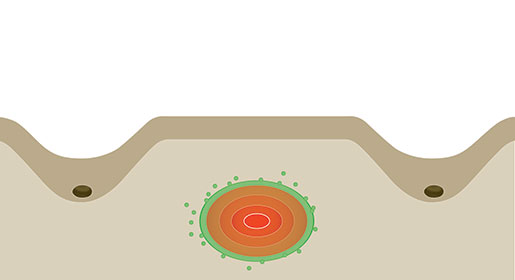

Step 1 - Ammonia

Ammonia (NH3 shown red) is initially released by ammonia and urea based fertilizer after it is applied. In this form, the fertilizer is dangerous to nearby seeds for two reasons:

- Ammonia is very toxic to all living things;

- Ammonia has a strong affinity for water, and will outcompete any nearby seeds for moisture.

These effects tend to magnify when available ground moisture is scarce.

With mid row placement of the bulk of nitrogen fertilizer, each seed has access to adequate nutrients for germination and early seedling growth within its own shell, the surrounding soil and with starter fertilizer placed in the seed row or independently in close proximity with the TriMax™ Triple-Shoot System.

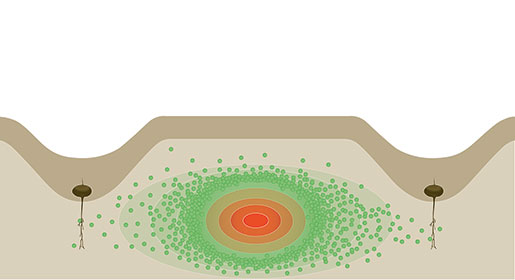

Step 2 - Ammonium

Ionic hydrogen transfer from water and clay particles convert ammonia to ammonium (NH4+ shown orange). Ammonium dissolves in soil water and can be absorbed by roots for plant growth. Ammonium is not very mobile in the soil, as it can be attracted to clay and organic matter. The rate of conversion to plant available nitrogen occurs very quickly, with access from the mid row band to the seedling roots within 2 days.

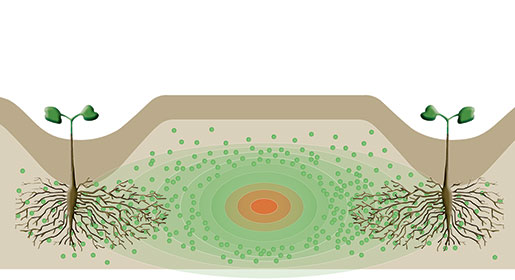

Step 3 - Nitrate

Certain bacteria in the soil will convert ammonium (NH4+) to nitrate (NO3- shown green). Nitrate is very mobile in the soil and is also susceptible to denitrification (loss as a nitrous oxide gas) or to leaching losses. Producers want to select fertilizer banding systems that minimize the amount of time that nitrate resides in the soil before the developing crop utilizes it.

With mid row bands, the developing root system accesses the nitrate as it moves away from the surface of the nitrogen band. The plant’s roots detect the nitrate and begin to proliferate towards the source. Research has shown that by the time the plant is in the 1 to 2 leaf stage, roots often extend outwardly 4 to 6 inches in a mid row banding environment.