Setting the correct operational depth, in relation to the soil surface and the seeding depth is vital. Attention and appropriate action will not only produce a good crop response to the banded fertilizer, but will also minimize losses of your valuable investment.

The key to effective and trouble-free operation is correct depth setting, as well as periodic greasing and scraper adjustment to account for disk wear. Proper setting will greatly reduce troublesome issues such as plugging or bearing failure.

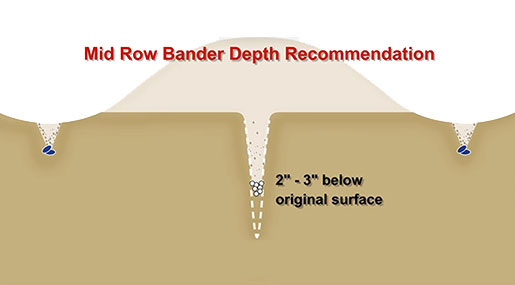

Typical Bander Depth Setting

It is recommended to set the MRBs® 2 to 3 inches below the original soil surface.

- Too shallow of a depth setting may not provide enough soil cover to prevent nitrogen loss through volatilization.

- When operating in dry conditions, adjust the working depth to ensure fertilizer is placed into moist soil.

- For NH3 application, excessive working depths may delay the closing of the furrow, reducing retention of anhydrous ammonia in the soil.

- Extended operation at excessive depths will increase draft, component wear and the increase the chance of plugging.

Note: Operational depth setting recommendations are similar for Mid Row Shank™ III fertilizer applicators. The goal is to ensure good soil cover of the fertilizer furrow to minimize loss to the air. Excessive seeding speeds may cause soil throw by the openers.

Depth Adjustment

MRB® Adjust - Add or remove shims to the cylinder rod to change operating depth. Spare shims are stored on upper cylinder pin if needed.

- 1/4 " thick shim = 5/8" depth adjustment

- 1/8" thick shim = 5/16" depth adjustment

Video Presentation

The key to trouble-free operation is to check the MRBs® periodically and adjust as needed for changes in seeding depth or disc wear.

This presentation will cover all the key settings and adjustments that will help ensure optimal performance during seeding.

It is important to refer to the Operator's Manual when making any adjustment to your equipment.