Hydraulic Recommendations

When determining the fan option that will best suit your requirements, consider:

- drill size and spacing;

- typical seeding speed and maximum expected product rates;

- hydraulic requirements of the air drill paired with the air cart;

- hydraulic capacity of the tractor.

The High-Capacity Fan is recommended if selecting an air drill equipped with an 8 or 10 port primary manifold.

- Is also an option for the TriMax™ seed line if the drill is equipped with 10-port primary manifolds.

- Provides the air capacity to deliver typical to high rates for large scale drills seeding at typical seeding speed.

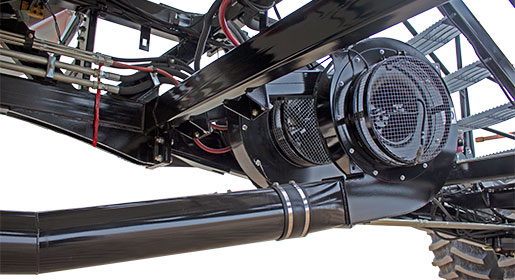

- The fan rotor is 3½" wide and is equipped with a 16 cc hydraulic motor that can achieve up to 6,000 rpm.

- To achieve maximum performance and reduce possible coupler failures, ¾" hydraulic couplers are required.

The High-Speed Fan is recommended for 60' and larger drills equipped with an 6 or 8-port primary manifold.

- Available for the third product line in a TriMax™ Triple-Shoot configuration.

- The fan rotor is 2½" wide and is equipped with a 12 cc hydraulic motor that is able to achieve up to 6,000 rpm.

- To achieve maximum performance and reduce possible coupler failures, ¾" hydraulic couplers are required.

The High-Pressure Fan is recommended for the 3420 ParaLink Hoe Drill™, 3330SE-86 or 3335QDA-86 PHD™ on 10" and 12" spacing and the 3720-70 or 3820-70 PCD™ on 10" spacing.

- The High-Pressure Fan is equipped with a large back swept rotor fitted with a 19 cc hydraulic motor.

- To achieve maximum performance, units equipped with the High-Pressure Fan have 1" hydraulic lines across the drill and air cart and ¾" hydraulic couplers.

The Regular Fan is only available on the 8000 Series Air Cart, or on the 6" seed line of a TriMax™ Distribution System on the 9000 I Series Air Cart.

| Fan Configuration |

Minimum (gpm) |

Recommended (gpm) |

| Single, Regular* |

9 |

13 |

| Single, High-Speed |

15 |

20 |

| Single, High-Capacity |

22 |

26 |

| Single, High-Pressure |

25 |

30 |

| Dual, High-Speed |

30 |

40 |

| Dual, High-Capacity |

44 |

52 |

| High-Speed & High-Pressure |

40 |

50 |

| High-Speed & High-Capacity |

37 |

46 |

| High-Capacity & High-Pressure |

47 |

56 |

* - 5,000 rpm max.

Recommended Hydraulic Flow Requirements

When operating independent seed drills, hydraulic flow requirements are highest when turning on the headlands. The recommended flow listed in the chart above allows the seeding system to be raised and lowered within two headlands. It should be noted that the recommended fan requirements are for the maximum operational speed (rpm) of the fan.

Minimum Hydraulic Flow Requirements

If the recommended values cannot be achieved, minimum flow will provide adequate performance in most instances. If the hydraulic flow is less than the recommended, the fans may slow down and the openers may lift slowly in the headlands. This may result in the requirement for three headlands. In typical operating conditions, one or both fans are operating at less than maximum output levels, which will reduce hydraulic requirements.

Regardless of fan selection, the use of ¾" hydraulic couplers will maximize fan performance. Avoid costly performance reductions by minimizing oil flow restrictions across the entire system.

Hydraulic Pressure Drop Off

With many tractors, maximum hydraulic flow drops off sharply prior to maximum operating pressure. By setting the tractor to a pressure setting of 3100 psi the hydraulic flow will be near the rated output at the maximum operating pressure.

Hydraulic Recommendations for Air Drills

It is important to consider the hydraulic requirements of both the drill and air seeder to ensure your tractor's hydraulics are up to the task.

|

ParaLink Hoe Drill™ Specifications |

|

Paralink Coulter Drill™ Specifications |

Minimum Fan Speed Requirements

|

Minimum Fan Speed Charts Page (Customer Service Section) |