LiftMaster™ Feature

Simplify with LiftMaster™; LiftMaster™ provides automatic lifting and lowering of the openers at the field headlands, eliminating this tedious task.

LiftMaster™ is standard on:

- 3330SE™, 3335QDA™ and 3420 ParaLink Hoe Drills™; and,

- 3720 and 3820 ParaLink Coulter Drills™.

LiftMaster™ is optional on:

- HD and CD Frame Mounted Seeders™.

All units must be paired with an air cart equipped with the X35 Apollo System.

Retrofit kits are available for previous Bourgault ParaLink™ hoe and coulter drills mated to an air cart equipped with the X35 or X30 Apollo Systems, 2015 model year or newer.

PackMaster™ Option

The PackMaster™ option achieves a uniform packing force across variable fields without manual adjustment.

PackMaster™ senses changes in the force required to maintain the seed opener in the ground and automatically adjusts the hydraulic pressure to the individual opener cylinders to maintain the packing pressure set by the Operator at the beginning of the field.

Models Available with PackMaster™:

- 3330SE PHDs™

- 3335QDA PHDs™

- 3420 PHDs™

- 3720 PCDs™

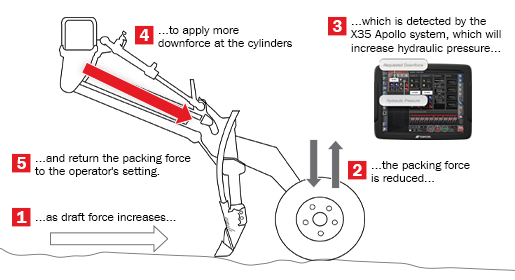

How It Works

One packer wheel spindle is equipped with a load cell that measures the actual packing force exerted on the ground by that packer tire:

- as the draft force increases;

- more force is required to keep the opener in the ground, reducing the force being applied by the packer wheel;

- this reduction is detected by the load cell, which sends a signal to the X35 Apollo System;

- the X35 Apollo System instructs the hydraulic system to increase the pressure;

- the increase in pressure increases the downforce at the hydraulic cylinder to restore the desired packing pressure.

The Operator must first calibrate the system and then set the desired packing force before seeding starts.

If you encounter a wet patch of soil while seeding, the system provides an "Emergency Float" option that allows you to turn off the down pressure, allowing you to "float" through the trouble spot without getting stuck!

Manual Opener Control

If the X35 is not selected, the Model 500 Control Box provides precise control so you can make manual adjustments as field conditions change during operation.

- PHD™ Openers - changes to the hydraulic pressure adjusts the downforce on the hoe opener/packer assembly.

- PCD™ Openers - changes to the hydraulic pressure adjusts the downforce on the cleaner/packer wheel assembly.

Opener Pressure Adjustment

Along with opener up/down control, the Model 500 provides downforce adjustment on the opener assemblies.

- Each increment of the up/down button provides a change of 50 psi of hydraulic pressure.

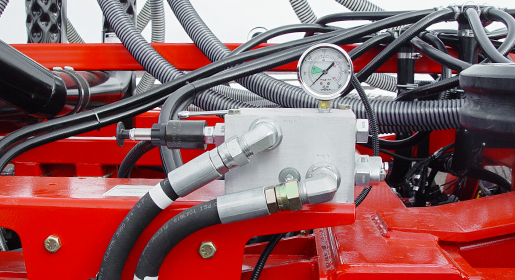

- A gauge on the hydraulic block allows you to verify the hydraulic pressure being displayed on the control box.

Note: The 500 Control Box is not available with the 3420 TransFold™ PHD™.